Teyi Gabion Baskets Factory

About Us

gabion manufacturing company

Our products include Gabion Baskets, River Gabion Matresses,Gabion Sacks, Rockfall Nets,Welded Gabions, Gabion Wall , Gabion Cage and other products.

Teyi Gabion Baskets Factory

gabion manufacturing company

Our products include Gabion Baskets, River Gabion Matresses,Gabion Sacks, Rockfall Nets,Welded Gabions, Gabion Wall , Gabion Cage and other products.

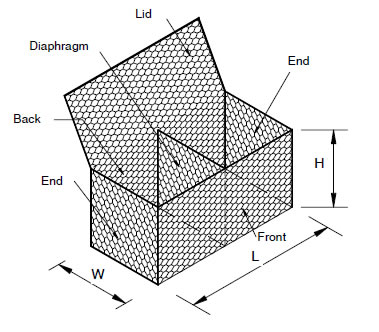

Figure 1

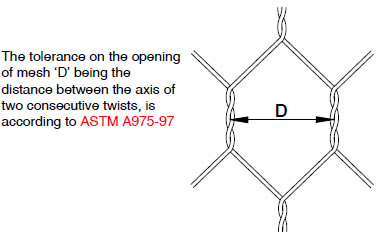

Figure 2

Gabions are baskets made of 8x10 double twisted steel woven wire mesh, as per ASTM A975-97 (Figs. 1, 2). Gabions are filled with stones at the project site to form flexible, permeable, monolithic structures such as retaining walls, channel linings, and weirs for erosion control projects.

The steel wire used in the manufacture of the gabion is heavily Galfan coated soft temper steel. A PVC coating is then applied to provide added protection for use in polluted environments where soils or water are acidic: in salt or fresh water, or wherever the risk of corrosion is present. The PVC coating has a nominal thickness of 0.50 mm. The standard specifications of mesh-wire are shown in Table 2.

The gabion is divided into cells by means of diaphragms positioned at approximately 1m centers (Fig.1). In order to reinforce the structure, all mesh panel edges are selvedged with a wire having a greater diameter (Table 3). Dimensions and sizes of PVC coated gabions are shown in Table 1.

Wire

All tests on wire must be performed prior to manufacturing the mesh.

1. Tensile strength: the wire used for the manufacture of gabions shall have a tensile strength between 372-470 according to ASTM A856. Wire tolerances (Table 3) are in accordance with ASTM A856.

2. Elongation: Elongation shall not be less than 12%, in accordance with ASTM A370-97. Test must be carried out on a sample at least 12 in. (30 cm) long.

3. Galfan coating: All wire shall comply with the requirements of ASTM A975-97, style 3 coating, Galfan and PVC coated steel wire.

4. Adhesion of Galfan: the adhesion of the Galfan coating to the wire shall be such that, when the wire is wrapped six turns around a mandrel having four times the diameter of the wire, it does not flake or crack when rubbing it with the bare fingers, in accordance with ASTM A856.

P.V.C. (Polyvinyl Chloride) Coating

The technical characteristics and the resistance of the PVC to ageing meet the relevant standards. The main values for the PVC material are as follows:

Specific gravity: 1.30-1.35 kg/dm3 in accordance with ASTM D792 Table 1

Hardness: between 50 and 60 Shore D, according to ASTM D 2240

Tensile strength: not less than 20.6 MPa , according to ASTM D412-92

Modulus of elasticity: not less than 18.6 MPa , in accordance with ASTM D412-92

Abrasion resistance: the percentage of the weight loss shall be less than 12%, according to ASTM D1242-92.

Creeping corrosion: max. penetration of corrosion of the wire from a square cut end shall be 1 in. (25 mm) when the specimen has been immersed for 2,000 hours in a 5% solution

HCl (hydrochloric acid 12 Be).

1. Table of sizes for gabions

| L=Length (m) | W=Width (m) | H=Height (m) | # of cells |

| 2 | 1 | 0.5 | 2 |

| 1.5 | 1 | 1 | 1 |

| 2 | 1 | 1 | 2 |

All sizes and dimensions are nominal.Tolerances of ¡à 5% of the width, height, and length of the gabions shall be permitted.

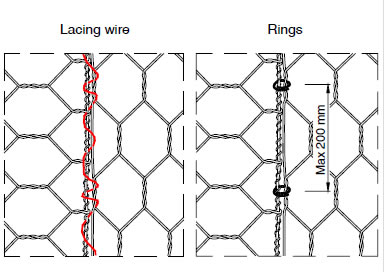

Figure 3

Figure 4

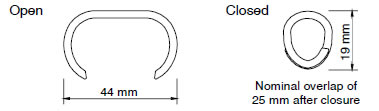

Lacing Operations

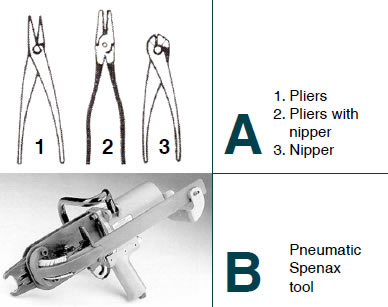

Lacing operations can be made by using the tools shown in

Fig.5. Stainless steel rings having the following specification

can be used instead of lacing wire (Fig.4):

Stainless steel rings for PVC coated products

diameter: 3.05 mm,

ASTM A313, Type 302, Class I

tensile strength: 1530-1745 MPa,

ASTM A313-92.

Spacing of the rings must not exceed 200 mm (Fig.3)

2. Standard Mesh-Wire

| Type | D (mm) | Tolerance | Internal Wire Dia (mm) | External Wire Dia (mm) |

| 8x10/ Galfan+PVC | 83 | ±10% | 2.70 | 3.70 |

3. Standard wire diameters

| Lacing | Mesh | Selvedge | |

| PVC Mesh Diameter mm | 2.2-3.2 | 2.7-3.7 | 3.4-4.4 |

| Wire Tolerance mm | 0.10 | 0.10 | 0.10 |

| Min. Quantity of Galfan gr/m | 200 | 244 | 260 |

Quantity Request

When requesting a quote, please specify:

size of units (length x width x height, see Fig.1),

type of mesh,

type of coating

EXAMPLE:

No. 100 gabions 2x1x1m - Mesh type 8x10 - Wire diam. 2.7/3.7 mm - Galfan + PVC coated

Figure 5