Welded mesh gabions are rigid wire baskets manufactured from cold drawn steel wire firmly electrically welded grid. The sturdy wire gabions are suitable for constructing sturdy soil retaining walls, architectural cladding facade, garden walls, planters, also used in flood control, highway sound control, and military defence uses.

Welded Gabion material: The wire is S.S. , Hot Dip Galvanised or Alu-Zinc alloy coated, ensuring a longer life. The meshes can then be polymer coated against corrosion and other weathering effects when used in salty and highly polluted environments.

Welded Gabion sizes:

1x1x1m welded gabion

1.5x0.5x0.5m gabion

1.5x1x1m gabion

2x1x1m gabion

500x500x500mm (Isreal)

Others.

Welded steel mesh size 1/2", 3/4", 1", 1 X 1/2", others.

Galfan gabions of welded mesh size: 3mm, 4mm, 5mm, others.

Welded mesh opening: Square, rectangular.

Coatings:

Hot dip zinc coated;

Electro galvanized;

Plastic / polyester coated green, black, grey;

Galfan.

GALVANIZED GABION BOXES of Welded Mesh - EURO Standard

Description:

According to EN 10218, EN 10223, EN 10244, EN 10245

Welded Mesh 80x100 mm

Wire 2.7/3.7 mm

Selvedge 3.4/4.4 mm

With Diapragm

With binding wire 2.2/3.2 mm (5% of gabions weight)

Size 2x1x1 m

Supplied with GEOTEXTILE

Tensile strength to DIN 53857

Permeability 400 l/m2/sec

100% Polypropylene

Weight 90 gr/m2

American Standard Welded Wire Mesh Gabions

Description: Galvanized wire mesh gabions, welded in sizes: 3'x3'x6' ,

3'x3'x12', 18"x 32"

Mesh type: Square

Hole

Galvanzing: Hot dip zinc galvanized

With door on the 18" side.

Standard: American standard

Gabion boxes 3'x3'x4' of welded wire sheet

Container cages of hot dipped galvanized welded mesh grid

Rock Gabions with nonwoven fabric and mesh fabric, USA standard

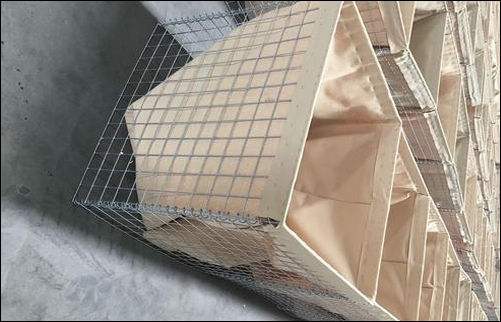

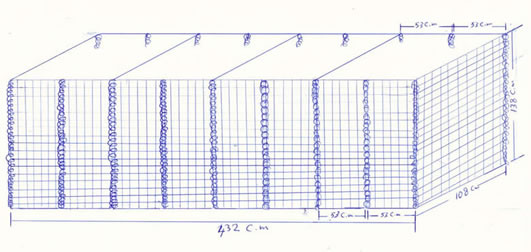

Galvanized Welded Gabion Box

To Jordan

Description:

Galvanized welded box gabions

Size 432 cm x 108 cm x 138 cm

Mesh 7.5 x7.5 cm net

Diameter of wire 4 mm

Tensile strength 650

with covering fabric inside box

2.0m x 1.0m x 1.0m Weldmesh gabion baskets with central partition,

England standard

Description:

Gabion units fabricated from electrically welded mesh panels compliant with bs en 10218-2 bs en 10244-2

Welded mesh size 762mm x 762mm x 3mm nominal wire diameter

Welded mesh wires have a tensile strength in the range 540-770 n/mm2, steel grade 0.10% arbon max, weld shear strength shall be a minimum 75% of the tensile strength of the wire

Corrosion protection to welded mesh panels lacing wire shall be tripple life galfan coating(95% zinc, 5% aluminium)

Gabion units assembly and binding:

Gabion units

factory assembled with stainless steel clips connecting side panels diaphragms to the base panel

Gabion units are supplied with lacing wire for site assembly, and lacing wire minimum wire 2.2mm for final jointing.

Cross-ties provided at 1m maximum horizontal centres before filling: the cross-ties shall comprise either internal welded mesh diaphragms or a double thickness of lacing wire positioned at mid-height

Adjacent gabion units jointed by continuous lacing across the joints at the front rear faces. The lids shall be wired down on all joints across the diaphragms

Gabion flll shall be hard, durable non frost susceptible rock the fill shall be graded 100-200mm, with 90% being retained on a 100mm diameter ring

The fill shall be carefully packed to minimize voids distortion of the gabion unit.

Binding Wire is needed for securing gabion mesh panels:

Material: Inox / SS wire, hot dipped galvanized wire, or galfan coated wire

For projects with high requirements for corrosion resistance, hot dipped galvanizing, galfan coating, stainless steel wire is used:

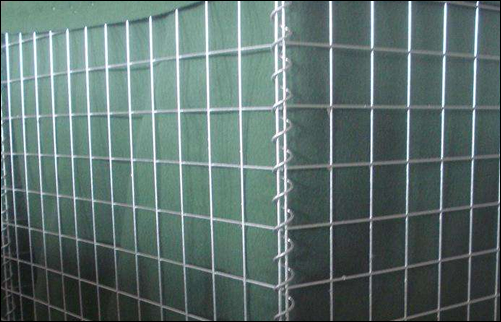

Gabions Weld Mesh

Steel mesh welded in SS INOX 304 or hot dip zinc coating wire material.

Welded gabions are made of square mesh or rectangular hole mesh:

Rectangular hole welded gabions:

Square Hole Welded Mesh Gabions:

Welded wire mesh gabions with the following technical specifications:

100 x 100mm welded wire mesh gabions 6 m x 2,4 m x 1m

Hole shape: Square hole

Wire: 4mm to 5mm wire thickness galvanized.

Modular Welded Mesh Gabions Project

We supply Welded Wire Net Gabion Basket for Harbor Enhancement Projects

QUALITY ASSURANCE

We supply gabion basket manufacture cut sheets or product informational materials for approval.

We supply the following products or materials samples for approval:

We build a mockup to verify selections made under sample submittals and to demonstrate aesthetic effects and set quality standards for materials and execution:

PRODUCTS DESCRIPTION

GABION BASKETS

Gabion baskets to consist of square wire mesh and be factory fabricated. The sides, ends, lid and internal diaphragms readily assemble at site into rectangular baskets of sizes as indicated. Gabions shall conform to the following:

FOUNDATION PREPERATION

The foundation on which the gabions are to be placed shall be cut or filled and graded to the lines and grades shown on the drawings. Surface irregularities, loose material, vegetation, and all foreign matter shall be removed from foundation surface area. When fill is required, it shall consist of materials conforming to the specified requirements. Gabions and bedding or specified geotextiles shall not be placed until the subgrade preparation is completed, and the subgrade surfaces have been inspected and approved.

Placement of separation geotextile and placement and compaction of stone base material will be required per plans and specifications. The surface of the finished material shall be to grade and free of mounds or dips. Extra care should be taken with stone base preparations in order to ensure a level and smooth surface for placement of baskets.

Drainage and filter geotextile fabrics shall be installed in accordance with the requirements of the plans and specifications. Ensure drainage fabric extends up rear faces of gabions, adjacent to soil retention, to prevent soil migration into stone fill material during and after construction.

INSTALLATION

Assemble baskets, modular diaphragms, stiffeners, and join adjacent baskets together, so that joints are as strong as mesh.

Place baskets in position prior to filling with stone fill material. Place the empty gabions on the foundation and interconnect the adjacent gabions along the top, bottom, and vertical edges using lacing wire or spirals.

FILLING BASKETS

After adjacent empty wire gabion units are set to line and grade and common sides properly connected, they shall be placed in straight-line tension to gain a uniform alignment. Staking of the gabions may be done to maintain the established proper alignment prior to the placement of rock. No temporary stakes shall be placed through geotextile material. Pre-formed stiffeners or connecting lacing wire may be attached during the filling operation to preserve the strength and shape of the structure.

The gabions shall be carefully filled with the stone fill material, using a combination of machine and hand methods, ensuring alignment, avoiding bulges, and providing a compact mass that minimizes voids. Machine placement will require supplementing with handwork to ensure the desired results.

Units shall be filled such that the mesh lid bears onto the stone fill. The lid shall be wired down on all joints and across the diaphragms. The use of crowbars or other single point leverage bars for lid closing is prohibited due to the potential for damage to the baskets.

Any damage to the wire or coatings during assembly, placement and filling shall be repaired promptly or the units shall be replaced with undamaged gabion baskets.

We welcome and help design modular gabions units.

Welded Wire Gabions for Croatia Construction Project

Welded gabions, wire 6mm, opening size: 100/50 mm, specification as following:

50/50/200 cm

50/50/150 cm

50/50/100 cm

50/50/100 cm

100/50/200 cm

100/50/150 cm

100/50/100 cm

More Applications - Welded Mesh Gabions Used in mass gravity retaining wall, decorative cladding and defensive barrier

The welded wire structure offers flat cladding and strong barrier filled with sand and rocks. Gabion weldmesh galvanised or stainless steel is rigid with no bends in the wire, making a uniform cladding effect. Welded gabion wall cladding is used for architectures in USA market and some Euro countries.

Gabion Cladding achieves constructional and aesthetic effects by securing a textured finish to buildings and walls.

Decorative gabions for public facilties:

Welded mesh gabions can be used in army protection wall barrier:

Gabions filled with sand or other materials can be used as barrier or fences: