We supply gabions made of heavily zinc coated soft temper steel wire galvanised then PVC coated for enhanced corrosion protection. We are a professional supplier certified under ISO 9001 and 14001 standards. All steel wire materials for gabion baskets manufacture comply with ASTM A975-11 or an equivalent standard.

Double twisted steel mesh gabions manufactured from flexible and sturdy soft temper steel offer both flexibility and long-lasting durability in erosion control and retaining walls applications. Zinc coated steel wire used conforms to Specification A 641,Class 3 coating, soft temper.

Features:

The soft steel wire offers flexibility for construction;

Double layer of zinc and PVC coating provides superior rust and corrosion resistance for long life;

Double twisted woven mesh creates a flexible structure for the gabion basket adjustable during construction and helps absorb impact from the infill rocks;

Double twisted wires are twisted together for increased strength and to prevent unraveling.

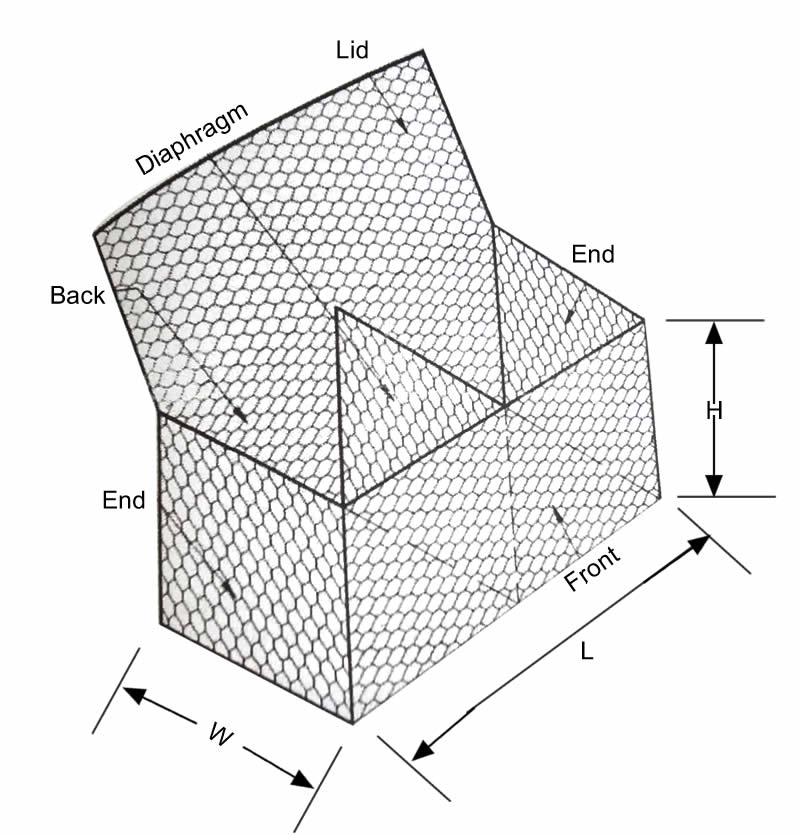

PVC Coated Gabion Boxes Made of Temper Steel Wire, for Rocks and Stones Filling in Channel Linings

Dimensions: 2x1x1m (LxWxH)

Number of cells- 2.

Material: Steel wire used in the manufacture of the gabion is heavily galvanised soft temper steel.

Properties of wire for gabions, including Tensile strength, Elongation, Zinc coating, Adhesion of zinc are listed below.

Gabions Wire Properties and Standards:

| Property | Unit | Standard Value | Test Value |

|---|---|---|---|

| Mesh Wire Diameter | mm | 2.70 ± 0.006 | 2.72 |

| Selvedge Wire Diameter | mm | 3.40 ± 0.07 | 3.41 |

| Lacing Wire Diameter | mm | 2.20 ± 0.06 | 2.24 |

| Opening Size | mm | 80 +16% | 83 |

| 105 | |||

| Tensile Strength of Mesh Wire (Before Weaving) | MPa | 400-500 | 451 |

| Tensile Strength of Selvedge Wire (Before Weaving) | MPa | 400-500 | 462 |

| Tensile Strength of Lacing Wire (Before Weaving) | MPa | 400-500 | 408 |

| Elongation of Mesh Wire (Before Weaving) | % | ≥ 12 | 17.5 |

| Elongation of Selvedge Wire (Before Weaving) | % | ≥ 12 | 15.5 |

| Elongation of Lacing Wire (Before Weaving) | % | ≥ 12 | 20.0 |

| Elongation of Mesh Wire (After Weaving) | % | ≥ 7 | 10.0 |

| Elongation of Selvedge Wire (After Weaving) | % | ≥ 7 | 10.0 |

| Zinc Coating of Mesh Wire | g/m² | 240 | 245 |

| Zinc Coating of Selvedge Wire | g/m² | 240 | 243 |

| Zinc Coating of Lacing Wire | g/m² | 240 | 246 |

| PVC Coating Thickness of Mesh Wire | mm | ≥ 1mm | 1.02 |

| PVC Coating Thickness of Selvedge Wire | mm | ≥ 1mm | 1.01 |

| PVC Coating Thickness of Lacing Wire | mm | ≥ 1mm | 1.04 |

Gabion Boxes Fabrication

Gabion mesh and wire:

Gabion boxes are constructed from Mesh #8 double twisted steel woven wire mesh, which conforms to A975-11 or an approved equivalent standard. The steel wire used in making gabions is coated with a layer of heavily zinc coated soft temper steel, followed by a PVC coating for added protection.

Sheet components:

Gabions are produced by mechanically connecting all components at a production facility. The front, base, back, and lid of the gabions are integrated into a single woven unit. Both ends and diaphragms are factory-connected to the base. The perimeter edges of the forming basket and the top or lid are reinforced with a selvedge made from wire of a larger diameter.

Binding and connecting:

The internal structure of a gabion box includes several cells, divided by diaphragms positioned. These diaphragms are securely fastened to the base and require no additional lacing on site. All binding and connecting wire used in the assembly of the gabions is also supplied.

Gabion Box Products Features

Gabion boxes are structured featuring compartments divided by diaphragms to enhance stability and performance.

Wire Specifications

Tensile Strength: The manufacturing and lacing wires have a tensile strength ranging from 350 to 550 MPa.

Elongation: The elongation rate not less than 10% when tested on a sample 300 mm in length.

Zinc Coating: The minimum zinc coating meets ASTM A641/A641M-09 for Class 3 or an equivalent standard such as EN10244-2class A, ensuring both quantity and adhesion of the zinc.

Testing Requirements

Wire mesh should meet the tensile strength, punch test resistance, and connection to selvages as per ASTM A975 or equivalent standards such as EN10223.

PVC (Polyvinyl Chloride) Coating

The PVC coating on the wires should conform to ASTM A975 and EN 10245 standards, ensuring a minimum thickness of 0.38 mm and a nominal thickness of 0.5 mm. The specific gravity should be between 1.30 and 1.35 according to ASTM D792-08.

Material Properties:

Hardness: Between 50 to 60 Shore D, according to ASTM D2240-05.

Tensile Strength: Not less than 20.6 MPa, as specified in ASTM D412-06a.

Modulus of Elasticity: Not less than 18.6 MPa, according to ASTM D412-06a.

Abrasion Resistance: Weight loss not to exceed 12% as per ASTM D1242-95.

Heat Aging Test: The PVC polymer coating will maintain its integrity under UV and abrasion conditions and is projected to last 60 years, in compliance with UL 746B.

Accelerated Aging Tests:

Salt Spray Test: 3000-hour duration, tested according to ASTM B117-11.

UV Exposure: 3000 hours at 63°C, following ASTM D1499-05 and ASTM G152-00.

Brittleness Temperature: Maintained above -90°C unless a lower temperature is specified by the buyer, tested per ASTM D746-07.

Post-Aging Properties:

Appearance: No visible damage such as cracking, stripping, or air bubbles, and no significant color variation.

Specific Gravity: Variation within 6%.

Hardness: Variation within 10%.

Tensile Strength: Variation within 25%.

Modulus of Elasticity: Variation within 10%.

Abrasion Resistance: Variation within 10%.

Brittleness Temperature: Not to exceed +80°C.

Assembly of Gabions

Temper Steel Wire Gabions are shipped in folded flat sheet in bundles.

Assembly of Gabions:

Gabion cages lids are placed to follow gabion lay-out plan for construction.

Gabions are installed to the line, grade and dimensions according to construction lay-out plan.

Lacing of gabions:

There are two ways for lacing operations:

Fixing by tie wire;

Fastening by steel rings (Galmac coated steel rings).