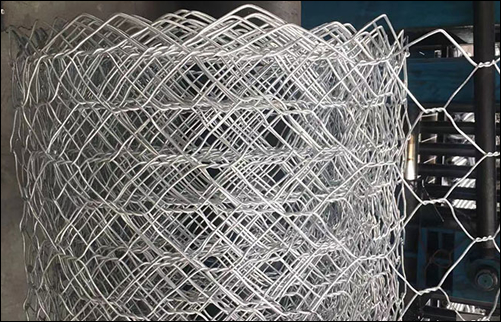

High strength woven wire mesh constitutes major parts of the rockfall netting security system.

Rock mesh roll length: 25 or 50 m or custom size.

Roll width: 1m, 2m, 3m, 4m or custom size.

Hexagonal Woven Gabions Rockfall Netting Classifications according to finishes:

Hot dipped galvanized;

PVC coated galv.;

Galfan galvanized.

Gabions Mesh Systems provide essential protection for slopes debris and falling rocks.

The mesh helps retain the rock debris between the slope and the mesh, to avoid the risk of injury or damage caused by slope.

Rockfall netting is covered over the slope and secured with anchor bolts to form a steel mesh drapery.

Gabions mesh is secured both at the top of the slope and at the foot of the slope with high strength cables.

Rocks and debris will fall to the foot of the slope behind the steel mesh drapery where rocks or debris can be then safely removed without causing injury or harms.

Main Components: Galvanized iron gabion mesh pvc coated, wire rope and steel rods

Supply of PVC coated galvanised gabion netting, wire ropes and steel rods system for Kenya Project in Civil/Road Building Works

Supply 1.5 metre long hot deep galvanized rods made of N32 reinforcement bars threaded on one side

Supply galvanized M32 nut

Supply galvanized flat plate 200x200x10mm thick flat plate

Supply and install woven hexagonal mesh rockfall netting

20mm dia. Galvanized PVC coated wire rope

20 mm dia. Termination grip

20mm dia. Ordinary thimble

Lacing wire

WOVEN HEXAGONAL MESH ROCKFALL NETTING

2.70 / 3.70mm Wire Diameter galvanized and PVC Coated Rock fall netting, with the following specifications:

MANUFACTURE: Rock fall netting shall be manufactured from double twist hexagonal woven mesh in accordance with BS EN 10223-3:1998.

MESH SIZE: The mesh openings shall be hexagonal and of a nominal dimension of 80mm x100mm.

MESH WIRE: The nominal wire mesh diameter for the body of the netting shall be 2.7mm in diameter and of a nominal 3.40mm for the edge selvedge wire. All wire shall be in accordance with BS EN 10218-2:1997.

The tensile strength falls within a range of 350 to 575 N/mm2.

CORROSION: Wire shall be zinc coated to BS EN10244-2 2001. An additional extruded u-PVC PROTECTION: coating of nominal 0.5mm radial thickness is applied over the galvanised wire.

JOINTING: Rock netting provided with lacing wire or stainless steel “C” rings for site assembly. The lacing wire has a nominal wire diameter of 2.2mm (all in accordance with the corrosion resistance requirement).

SPECIFICATIONS FOR HOT DIPPED GALVANIZED STEEL RODS

Hot-dipped galvanized steel rods are galvanizing in accordance with ASTM specification Specifying hot-dip galvanizing for high-quality galvanized coatings. The galvanizing of the rods , nuts and the base plates are to be centrifuged or handled to remove excess zinc (such as bolts and similar threaded fasteners, castings and rolled, pressed and forged items) in accordance with Specification A153/A153M.

Galvanized Wire Double Twisted Woven Net Protection Fencing

6x8 mesh, mesh wire 2.7mm, selvedge wire 3.4mm

Supplied in mesh roll: 25 x 2m.

Galfan ( Aluminum and Zinc ) Wire Hexagonal Netting for Slope Protection System

8x10 hexagonal net, mesh wire 3.4 mm, selvedge wire 4.4mm

High Strength Rockfall Mesh Drapery

High Strength Aluminum Rockfall Mesh Drapery: Covering system of double twisted mesh and high tensile steel cables, designed for rock consolidation project. Supplied in 40’x80’ mesh rolls, to USA

Project of Rock Debris Security Netting

DOUBLE TWISTED PROTECTION MESH

Double twisted mesh gabion rolls 2.7mm wire diameter, 25m length,

8 x 10cm mesh size. Supplied to Lebanon, CIF Beirut.

Galfan coated double twisted steel wire mesh is popularly used as Rock fall net. The steel wire heavily galvanized with Galfan and the double twist woven flexible mesh structure can withstand the force of falling stones / rocks without breaking.

All wires are tested to meet or exceed following quality, prior to manufacturing the mesh:

1. Tensile strength: the wire used for the manufacture of rockfall net drapery shall have a tensile strength between 380-550 N/mm 2, above

EN10223-3 standard.

2. Elongation: Elongation shall not be less than 10%, according

to EN10223-3.

3. Galfan coating: minimum quantities of galfan meet the requirement s of EN10244-2.

4. Adhesion of galfan: the adhesion of the galfan coating to the wire shall be such that, when the wire is wrapped six turns around a mandrel having four times the diameter of the wire, it does not flake or crack when rubbing it with the bare fingers, in accordance with EN10223-3.

5. Outwearing accelerated aging tes in accordance with EN ISO 6988.