Plastic geogrids used in civil engineering are typically made from high-density polyethylene (HDPE) or polypropylene (PP) for strength and durability. Plastic Geogrid is used with gabions for soil retaining and river bank protection gabion wall construction works.

Geotextile fabrics and grids are all synthetic non-woven materials for gabions works: Geo textiles are used as drainage and filter cloth, geogrids are mainly used for reinforcing, stabilizing, and separating soil in construction projects.

1,Plastic geogrid: High-density polyethylene (HDPE), polypropylene (PP), or polyester (PET).

2,Fiberglass Geogrid

Different Geogrid Materials we supply are made for different uses:

Three Major Geogrid Structures

Uniaxial, Biaxial, Triaxial.

Biaxial Geogrid: Biaxial geogrids have a square or rectangular grid pattern with ribs that run in both directions. Biaxial geogrids can be used in a wider range of applications in reinforcing soil foundations, retaining walls, and embankments. Biaxial plastic geogrids offer a good balance between cost, performance, and ease of installation for gabion works.

Triaxial Geogrid: Triaxial geogrids have a 3-dimensional structure with ribs running in all three directions (longitudinal, transverse, and vertical). Ideal for applications in soft soil conditions or steep slope stabilization.

Fiberglass Geogrid

Fiberglass Geogrid with asphalt coated 40kn x 40kn

Geogrid composite (50kN Bi-axial Fibreglass Geogrid Knitted with 140 Gsm PP non-woven Geotextiles)

Geogrid is used to reinforce:

Dyke;

Roadbed;

Side slope;

Tunnel wall;

other reinforcing construction works.

Benefits:

1. Increase the bearing capacity of the roadbed and foundation and prolong their service life.

2. Prevent road surface and foundation from sinking or flawing, keep clean and beautiful ground surface.

3. Convenient construction saves time and labor, reduce mounting time and decrease maintenance expense.

4. Prevent culverts from flawing.

5. Enhance earth slope and prevent water loss and soil erosion.

6. Decrease underlayer thickness and save manufacturing cost.

7. Enhance the stability of side slope turf net patch to improve greening.

8. Replace wire netting used in mine as intermediate ceiling netting.

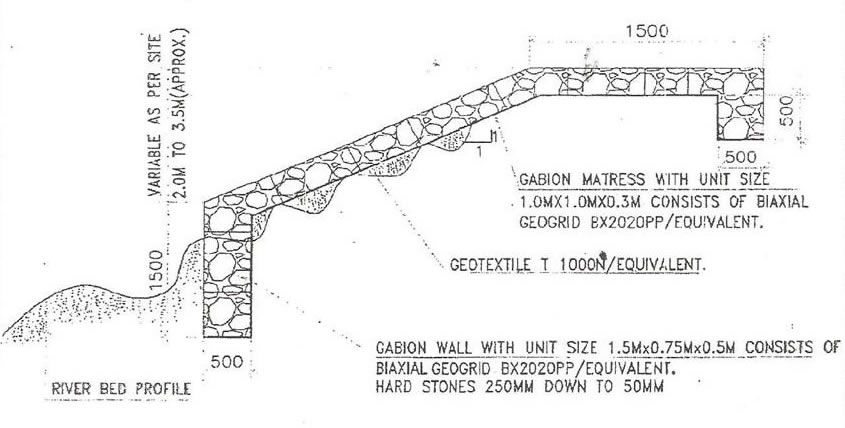

Mattress with Gabion filled with Hard Stones of 250-50mm nominal size

Gabion mattress size: 1.0m x 1.0m x 0.3m

Gabion wall size: 1.5m x 0.75m x 0.5m

Laying Geotextile grid over the prepared surface, the minimum lap length is 250mm.

Biaxial Geogrid (20K N/M) Specification

Material: Polymer Biaxial oriented Polypropylene

| Property | Unit | Test method | Value |

| Aperture size | MD (mm) CD mm |

Nominal | 43.7 41.9 |

| Ultimate tensile strength | MD kN/ mtr CD kN/ mtr |

ASTMD 6637 | 24.8 19.4 |

| Strain at ultimate | MD% CD% |

ASTMD 6637 | 8.6 8 |

| Tension at 2% Strain | MD kN/ mtr CD kN/ mtr |

ASTMD 6637 | 11.1 8.5 |

| Tension at 5% Strain | MD kN/ mtr CD kN/ mtr |

ASTMD 6637 | 20.7 16 |

| Junction Strength | MD kN/ mtr CD kN/ mtr |

GR 1-GG 2 | 26.0 19.9 |

| Flexural rigidity | MD mg-cm CD mg-cm |

ASTMD 1388 (Modified) | 509221 503875 |

| Roll Width | M | Minimum | 3.9 |

| Roll Length | Mtr | Minimum | 50 |

Gabion Retaining Wall Construction

Drawing:

Notes:

All dimensions are in mm

Gabion wall made up of gabion mattress and biaxial geogrid BX2020 PP or equivalent.

Gabions are made with 250mm to 50mm norminal size hard stones.

Gabion units are tied with adjacent units.

Gabion wall to be constructed after making trench of minimum 1.0m deep below river bed.

Bank of river edge is cut to slope not steeper than as shown in drawing. Bottom of slope shall be compacted well. Slope may be made with available local soil. Constructed bank slope should have minimum 95% standard proctor density.

Gabions zinc coated, 3x1x1m, Mesh Type 6x8, wire diam. 2, 70 mm, with diaphragms

Gabions zinc coated, 1,5x1x1 m, Mesh type 6x8, wire diam. 2,70 mm

Gabions delivered with all needed components and materials for assembly ( lacing wire, stiffeners) ; lacing wire is zinc coated , diameter 2.2 mm

Nonwoven geotextile grid, length 120 m width 3 m

Tools for lacing operations

Geogrid 100% PP, with anti-UV treatment

Grid thickness 20 mm

MD/TD: 43kN/m - 20kN/m

Reinforced with galvanised (+PVC) grid mesh size 80 mm

Specifications:

Geogrid:

Geogrid (UV Protected) similar Tensar BX 1200 (UV Protection) or approved equal quality.

Nonwoven Fabric, Amoco nonwoven style 4553 or equal quality.

Description:

Geogrid (uv protected)

Non-woven fabric

Degradable dbl net straw blanket

Wood anchors

Silt fence 24" x 100' w/ 10' post spacing

The tensile strength of pp geogrid is higher than that of the diamond mesh used in mining.

Features:

High-strength material and the mesh joint is firm

Low extension: Low unit extension, average stress, and avoid the appearance of the tuck net effectively.

Light: Weigh about 1kg/m2, with less labor intensity, improved working efficiency, and simple installation.

Safety: Static resistant, inflaming retarding, avoid the appearance of the electric sparkle effectively.

Erosion resistance: PP and PE surface ensures long service life and no invalidation caused by the erosion.

Technical indexes of the Geogrid for mining

| Spec Item | Unit | Using for intermediate ceiling | Using for side protection net | |

| Width | m | 1—3 | 1—3 | |

| Mesh size | mm | 50±4 | 50±4 | |

| Drawing force of the single mesh | ≥N | 4000 | 2000 | |

| Tensile stretch of the single mesh | ≤% | 5 | 5 | |

| Stripping force of the joint | ≥N | 50 | 50 | |

| Resistance of the product’s surface | <Ω | 1.0×109 | 1.0×109 | |

| Fire out time | ≤S | 10 | 10 | |